Thanks for asking!

Waveform Plastics is a family-run business and everyone takes a very active role in managing each and every order, ensuring we meet cost, quality and delivery expectations.

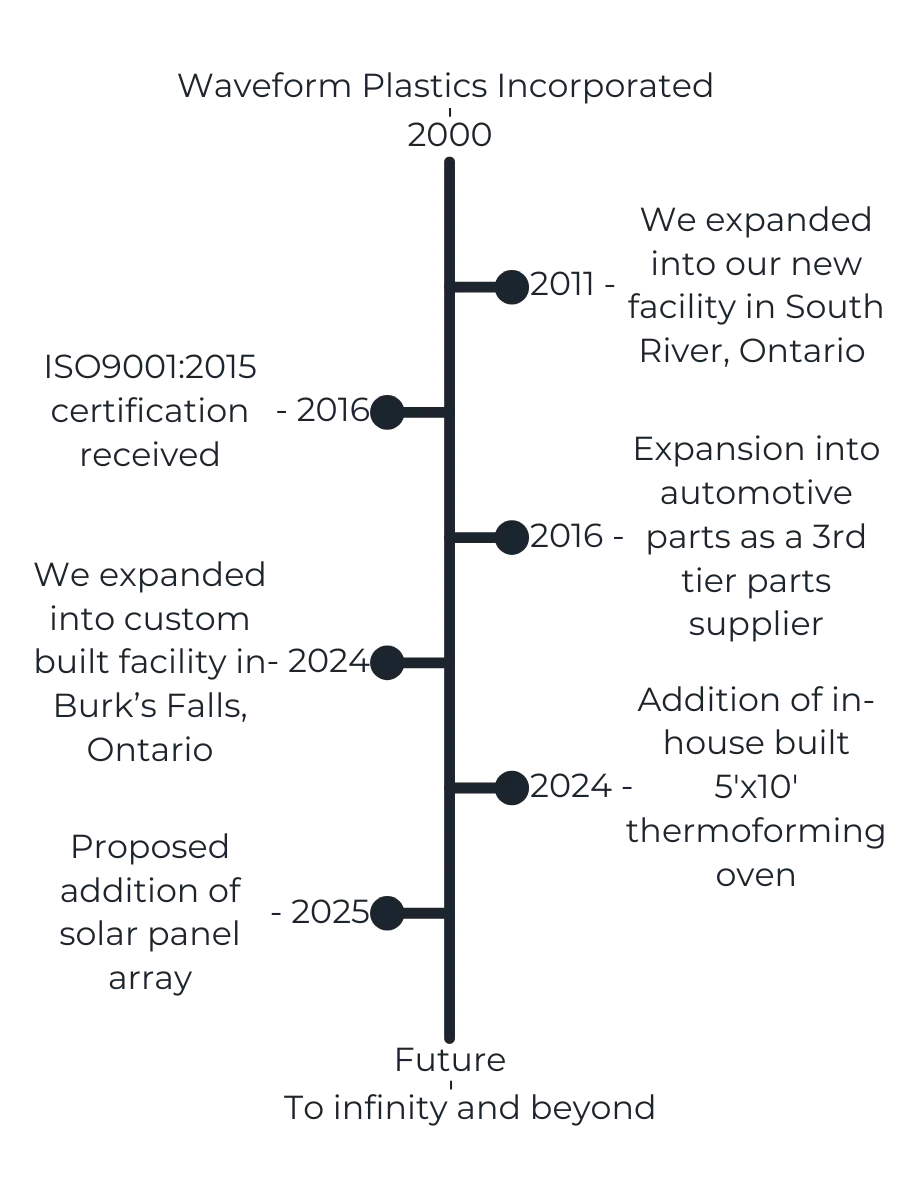

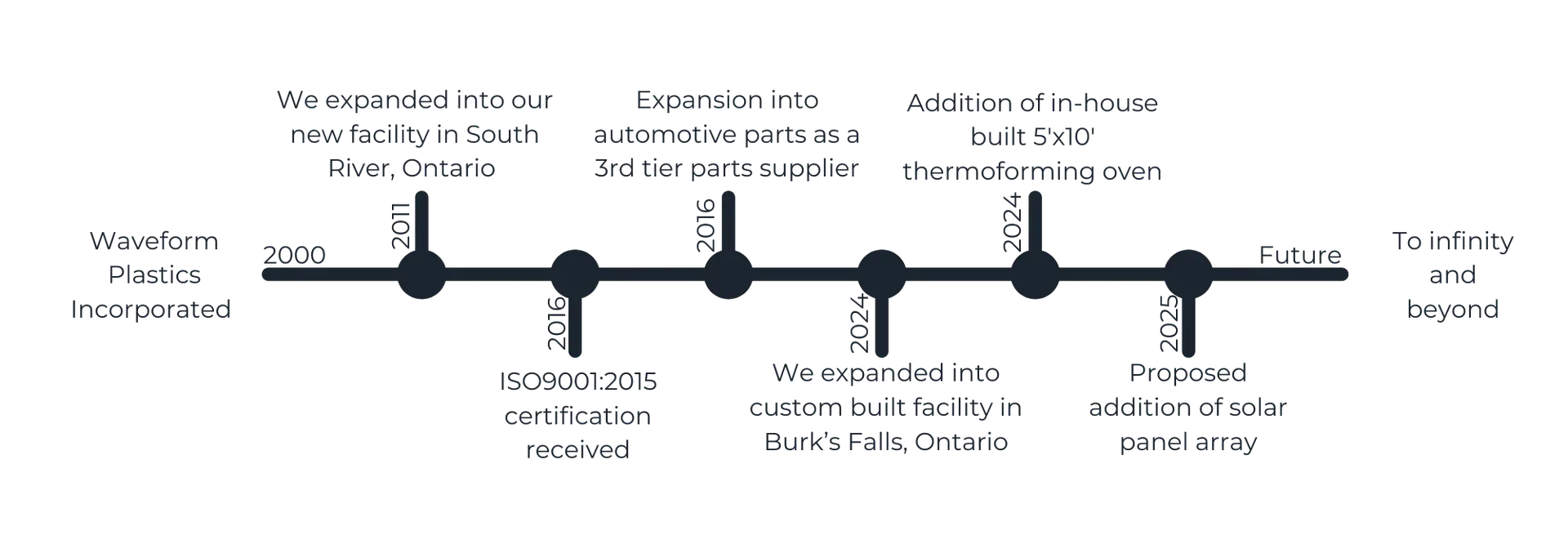

Waveform was incorporated in 2000, initially forming parts primarily for the marine industry. New opportunities followed quickly, and we expanded into many other areas, including industrial, medical, recreation, signage, and more.

With this growth came investment in new equipment and capabilities. We added new thermoforming and CNC machining equipment and advanced design capabilities with Solidworks. In 2011 we moved into much larger facilities, allowing us to grow further and become more efficient.

In 2015 we saw an opportunity to become a supplier to the automotive industry, and pursued ISO9001 certification, which we achieved in 2016. Our ISO9001:2015 certified Quality Management System is a cornerstone to not only our quality, but also our growth, customer satisfaction, and continuous improvement efforts.

That led to new opportunities in the medical industry, supplying components for such things as medical lifts and hospital beds.

With that continued growth came the opportunity to construct a new, custom designed 20,000 square foot building. This facility offers a greatly improved work environment, greater production efficiencies than ever before, integrated building and machine automation, and energy monitoring.

We were up and running at our new location by mid-2024.

One aspect of Waveform Plastics that has been a major asset to us is the talents of our core team. We span business management, tooling design and fabrication, machine building, software and automation. This is one of the things that we believe makes use unique – we’re very hands on when it comes to our equipment and processes. We’ve designed, built, and refined our own custom thermoforming machines and control software to work exactly how we want them to.

We continue to innovate our auxiliary processes and control integration. If we can dream it, we can build it!

We care about the environment too! We make every effort to minimize our footprint on this planet we love. Processes are designed to optimize the use of plastic, minimizing waste from the start. Wherever possible, all excess plastic is recycled, used by our suppliers to produce new material that we will use for future products. Our facility is designed from the ground up to be as energy efficient as possible. We are in the process of installing a solar power system on our building, which will help reduce peak demand, and will generate energy that we can feed back to the grid when we don’t need it.

That’s just one more way we’re investing in everyone’s future.

Waveform continues to innovate and grow. We can’t wait to see where we’ll be next month, next year, and into the next decade!

Let our amazing team bring your next project to life.

Just click here to get started!